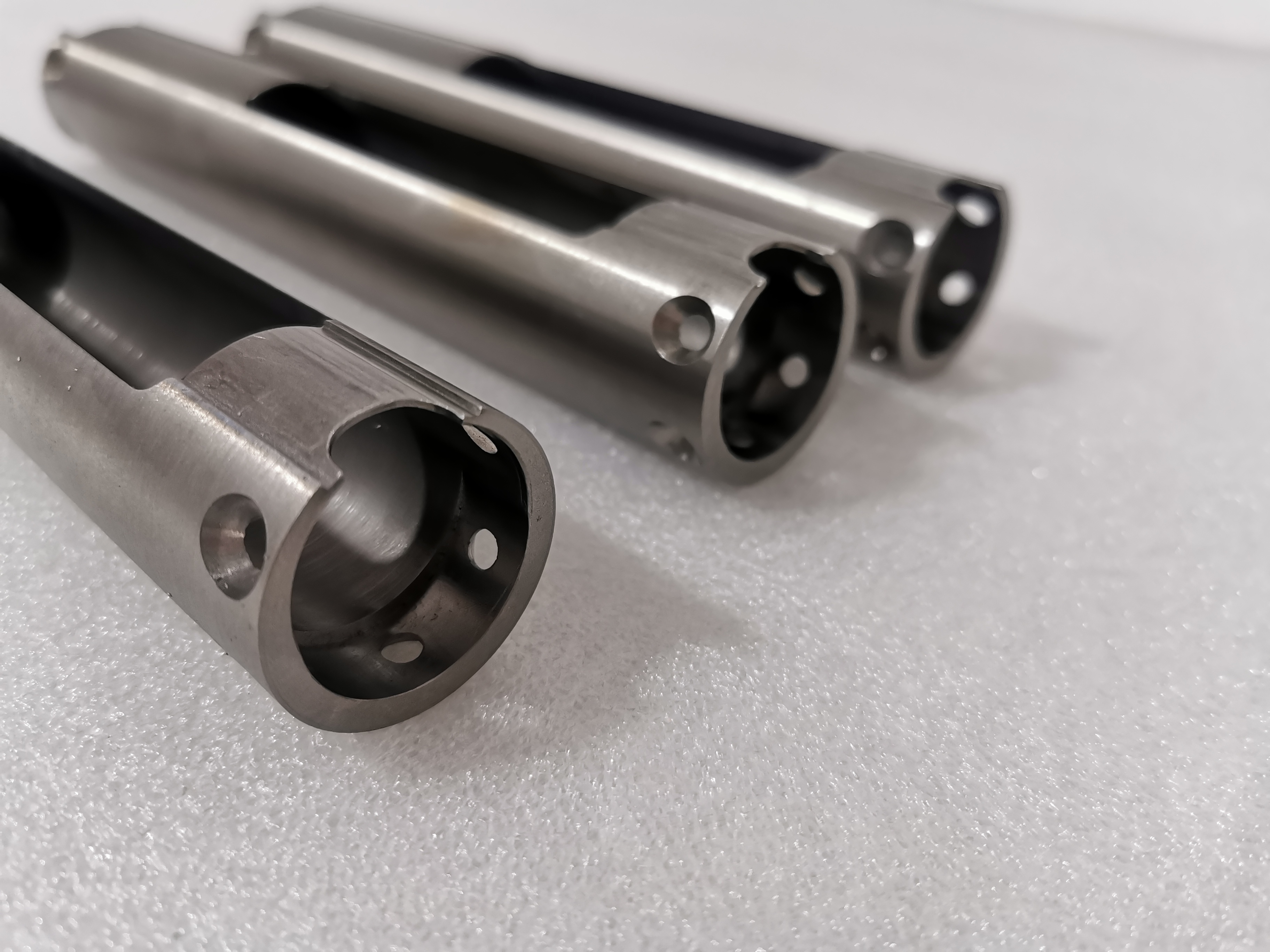

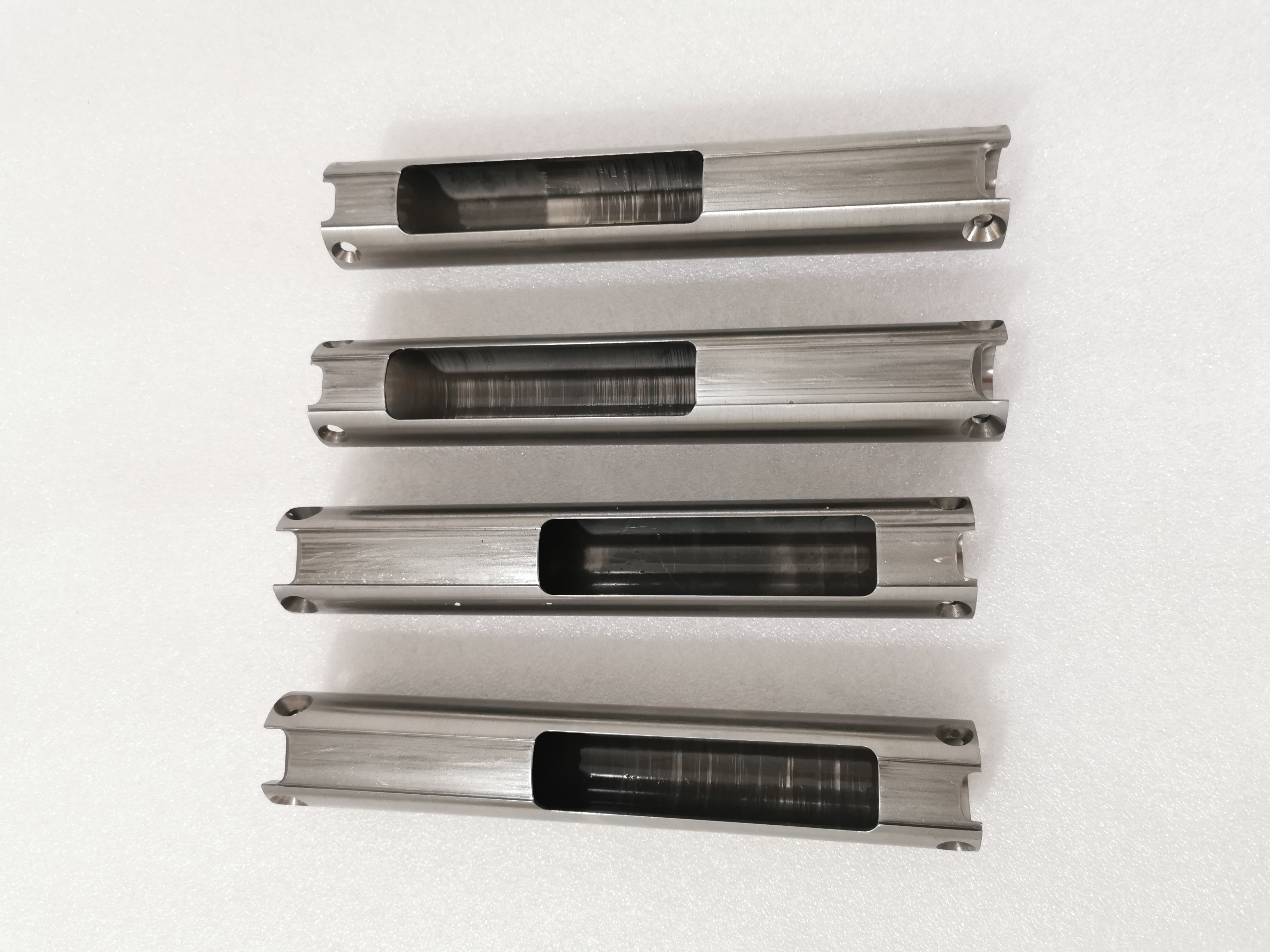

Gamma Ray Tiv Thaiv Tungsten Hluav Taws Xob Shielding Shielding Raj

Kev piav txog

Tungten npib hlau hlau yog tus cwj pwm siab yog tus cwj pwm siab, lub zog zoo thiab muaj qee qib ntawm Ferromagnetism. Muaj cov ntsej muag zoo thiab lub tshuab muaj peev xwm, lub zog zoo thermal thiab conductivity, thiab kev puas tsuaj zoo rau gamma rays lossis xoo hluav taws xob.

ZZCR yog lub ntiaj teb cov khoom lag luam ntawm cov shungsten hluav taws xob tiv thaiv qhov chaw thiab peb tuaj yeem muab cov ntaub thaiv hluav taws xob tiv thaiv qhov chaw raws li koj daim duab.

Tungsten Alloy hluav taws xob hluav taws xob cov ntaub thaiv yog tsim kom tsuas yog pub cov hluav taws xob kom dhau qhov uas nws xav tau tiag tiag. Peb lub teeb hluav taws xob tungsten tau lees tias kev nthuav dav hluav taws xob tau khaws cia tsawg kawg nkaus thaum lub sijhawm X-Ray Rauv thiab muaj kev tiv thaiv hluav taws xob.

Tungsten Alloy hluav taws xob teeb meem tau muaj kev nyab xeeb dua li lwm cov khoom zoo sib xws, vim tias cov khoom lag luam zoo sib xws thiab tsis muaj tshuaj lom thaum muaj kev kub ntxhov.

Tungsten Hluav Taws Xob Shielding Cov Kev Siv

1: Cov Thawv Scoratory

2: Gamma hluav taws xob shielding

3: daim thaiv thaiv thaiv

4: roj av drilling khoom

5: X-ROOD POJ

6: Tungsten Alloy Tsiaj Shielding Cheebtsam

7: Cov Khoom Siv Kho Mob Shielding

Lub cev thiab cov kws kho tshuab ntawm tungsten alloy (W-Ni-FE & W-NI-CU)

| Lub cev thiab cov kws kho tshuab ntawm tungsten alloy (w-ni-fe): | ||||

| Lub npe | 90wnife | 92.5WNife | 95wnife | 97WNife |

| Khoom | 90% w | 92.5% w | 95% w | 97% w |

| 7% ni | 5.25% ni | 3.5% ni | 2.1% ni | |

| 3% FE | 2.25% FE | 1.5% FE | 0.9% Fe | |

| Ntom ntom (G / CC) | 17gm / cc | 17.5gm / cc | 18gm / cc | 18.5gm / cc |

| Ntaus | Hom II & III | Hom II & III | Hom II & III | Hom II & III |

| Kev nyuaj | HRC25 | HRC26 | HRC27 | HRC28 |

| Cov Khoom Sib Nqus | Sib nqus me ntsis | Sib nqus me ntsis | Sib nqus me ntsis | Sib nqus me ntsis |

| Thermal conductivity | 0.18 | 0.2 | 0.26 | 0.3 |

Khoom nta ntawm tungsten hluav taws xob shielding raj

1: Tshwj xeeb nqus: feem ntau xws li ntawm 16.5 txog 18.75g / CM3

2: Lub zog siab: Lub zog tensile yog 700-1000MPA

3: Muaj Zog Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Txav Muaj Peev Xwm: 30-40% Siab dua li kev coj ua

4: siab thermal conductivity: lub thermal conductivity ntawm tungsten alloy yog 5 zaug uas ntawm pwm hlau

5: Tsawg coefficient ntawm thermal expansion: tsuas yog 1 / 2-1 / 3 ntawm cov hlau lossis hlau

6: Kev ua haujlwm zoo; Dav siv nyob rau hauv qhov teeb pom kev zoo thiab vuam kev lag luam vim nws txoj kev ua haujlwm zoo.

7: Muaj kev sib cav zoo nkauj thiab cov peev xwm.

Khoom Siv Ntau Lawm

Kev sib tsoo ntub

Txau Kom Qhuav

Thawb

Nias

Semi-Xovxwm

Ntsiav Sintering

Cov Khoom Siv Ua

Kev drilling

Hlau Txiav

Ntsug sib tsoo

Universal sib tsoo

Dav Hlau Sib Tsoo

CNC Milling Tshuab

Soj ntsuam ntsuas

Kev kub ntxhov

Kev khaatimimimat

Quadratic lub cim kev ntsuas

Cobalt Magic Ntsuas

Metallographic tsom