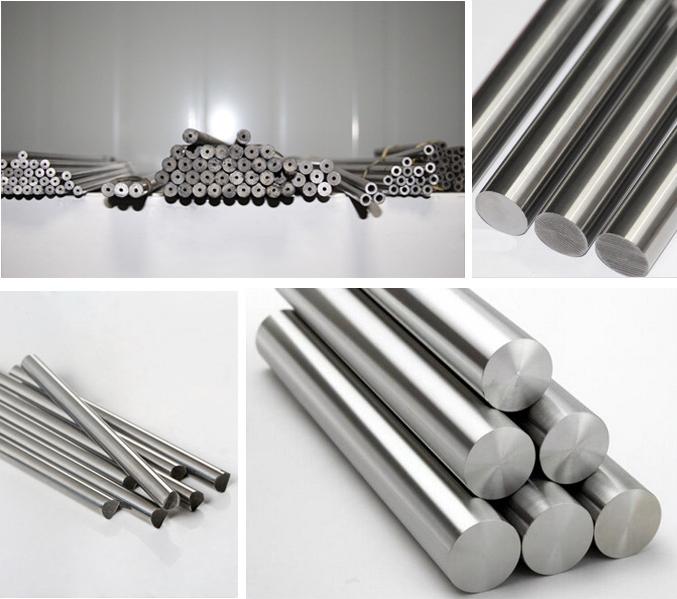

Muaj ob txoj kev sib sau rau kev tsim cov tungsten carbide round: ib qho yog extrusion yog ib txoj kev haum los tsim cov kab ntev. Nws tuaj yeem raug txiav rau txhua qhov ntev xav tau los ntawm tus neeg siv thaum lub sijhawm ua tiav. Txawm li cas los xij, tag nrho ntev tsis tau tshaj 350mm. Lwm tus yog compression moulding, uas yog ib txoj hauv kev los tsim cov khoom lag luam luv luv. Raws li lub npe qhia, cemented carbide hmoov yog nias rau hauv cov duab nrog pwm.

Cemented carbide muaj cov yam ntxwv zoo heev xws li kev ua kom muaj zog, qhov tseem ceeb tshaj plaws, kub ua rau muaj kev hloov pauv, thiab tseem muaj lub siab tawv ntawm 1000 ° C. Cov Hlau Tungsten yog siv dav ua cov cuab yeej, cov hlau thiab lwm yam hlau thiab lwm yam hlau thiab lwm yam khoom siv nyuaj, thiab cov pob zeb nyuaj, cov pob zeb nyuaj, cov pob zeb, kom qhuav txee, Z-tov khoom, granulator ----), nias (nrog rau sab siab hydraulic xovxwm lossis extruder), --- stertruder (degreasing rauv, sib xyaw ua ke so kom sov).

Cov ntaub ntawv raw yog ntub kev sib tsoo, ua kom qhuav doping, tom qab ntawd kom qhuav ntxiv tom qab molding, thiab thaum kawg tsim qhov kawg alloy los ntawm debinding thiab sintering thiab sintering.

Qhov tsis zoo ntawm cov voj voog bar extrusion kev tsim khoom yog tias kev ua haujlwm ntau lawm yog ntev. Muab cov kab sib txuas me me nyob hauv qab 3mm thiab tawg ob qhov kawg yuav nkim qee cov khoom siv. Qhov ntev ntev ntawm lub carbide me me taub txoj kab uas hla bar, tus phem zuj zus ntawm qhov seem. Ntawm chav kawm, ncaj thiab kev sib tw teeb meem tuaj yeem txhim kho los ntawm cylindrical sib tsoo ntawm ib theem tom qab.

Lwm tus yog compression moulding, uas yog txoj kev luv bar Tshuag yog tsim tawm. Raws li lub npe pom zoo, nws yog cov pwm uas nias cov khoom ua kom cov pa tawm ntawm cov duab carbide rau hauv cov duab. Qhov zoo dua ntawm carbide bar txoj kev sib haum qauv yog tias nws tuaj yeem tsim nyob rau hauv ib qho dhau thiab txo cov seem. Yooj yim piv cov txheej txheem xaim xaim thiab tshem tawm cov khoom siv qhuav los ntawm kev rho tawm txoj kev sib tw. Lub sij hawm shortened saum toj no tuaj yeem txuag cov neeg muas zaub 7-10 hnub.

Nruj me ntsis kev hais lus, isostatic nias kuj tseem yog rau compression moulding. Isostatic nias yog cov qauv zoo tshaj plaws rau kev tsim cov loj thiab ntev tungsten carbide round. Los ntawm cov ntawv sab sauv thiab qis dua piston, lub siab twj tso kua mis txhaj tshuaj nruab nrab ntawm cov roj hmab siab los ntawm cov roj hmab uas muaj kev lom zem nias rau kev sib sau.

Lub Sijhawm Post: Jan-24-2024