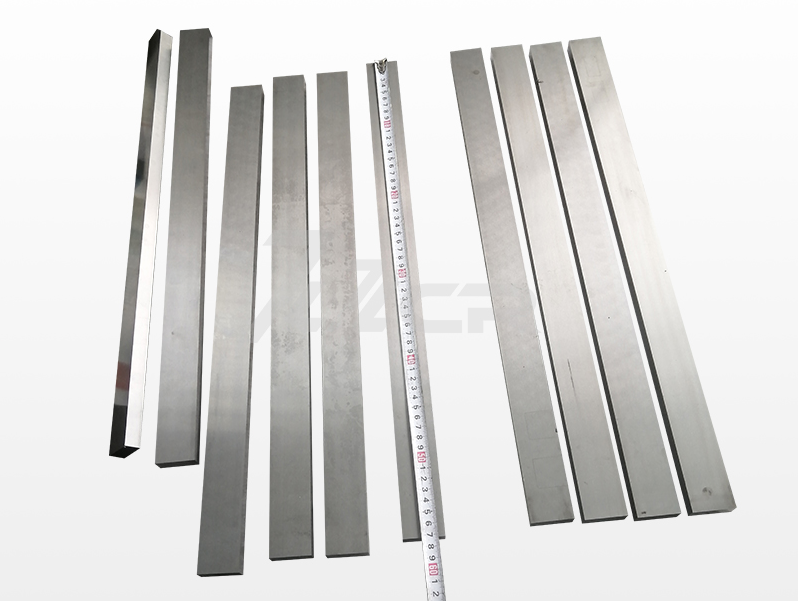

Tungsten carbide sawb yog ua los ntawm WC Tungsten carbide thiab steralurgical txheej txheem yog tsis zoo ib yam, thiab siv ntau heev.

Ib qho ntawm cov ntaub ntawv feem ntau ntawm tungsten carbide strips, nws yog muaj npe vim nws daim duab plaub (lossis hu ua tungsten carbide sawb / daim hlau. Tungsten carbide sawb muaj qhov nyuaj heev, cov tshuaj tua hluav taws xob zoo, cov tshuaj lom neeg tsis tshua muaj zog, thermal thiab hluav taws xob ua kom zoo sib xws nrog cov hlau thiab cov alloys.

Dab tsi yog vim li cas rau lubdesolderingntawm tungsten carbide strips? Chuanegrui Carbide yuav teb Tom ntej:

(1) Lub ntsej muag ntawm Tungsten carbide tsis yog qhuav los yog polished ua ntej cov hlau ntoo thiab tsis muaj zog ntawm lub zog ntawm Weld.

(2)Desolderingtseem yuav tshwm sim thaum tus neeg sawv cev ntawm tus neeg sawv cev tsis raug xaiv thiab siv Brazing tus neeg sawv cev, thiab cov khoom siv brazing tsis tuaj yeem ua tau zoo wetted ntawm cov npoo av, thiab covdesolderingtshwm sim tshwm sim.

(3) Qhov ntsuas kub yog li 30 ~ 50 ° C saum toj no melting taw tes ntawm cov hlau brazing, thiabdesolderingyuav tshwm sim yog tias kub siab dhau los yog tsawg dhau. Cua sov dhau lawm tuaj yeem ua rau oxidation hauv Weld. Siv zinc-muaj cov hlau brazing yuav muab cov weld xiav lossis xim dawb. Thaum lub ntsuas kub brazing yog tsawg dhau, cov tuab siv Weld yuav tsim, thiab sab hauv ntawm Weld yuav them nrog porosity thiab sluag suav nrog. Ob qhov xwm txheej saum toj no yuav txo lub zog ntawm Weld, thiab nws yooj yim rau Deweld thaum ntse lossis siv.

(4) Hauv cov txheej txheem Brazing, tsis muaj kev tawm suab qeeb lossis tsis txaus ntawm tus neeg sawv cev ntawm Weld, uas txo lub zog ntawm Weld thiab cov laj thawjdesoldering.

Lub Sijhawm Post: Lub Yim-28-2024