Tungsten carbide phaj rau pwm

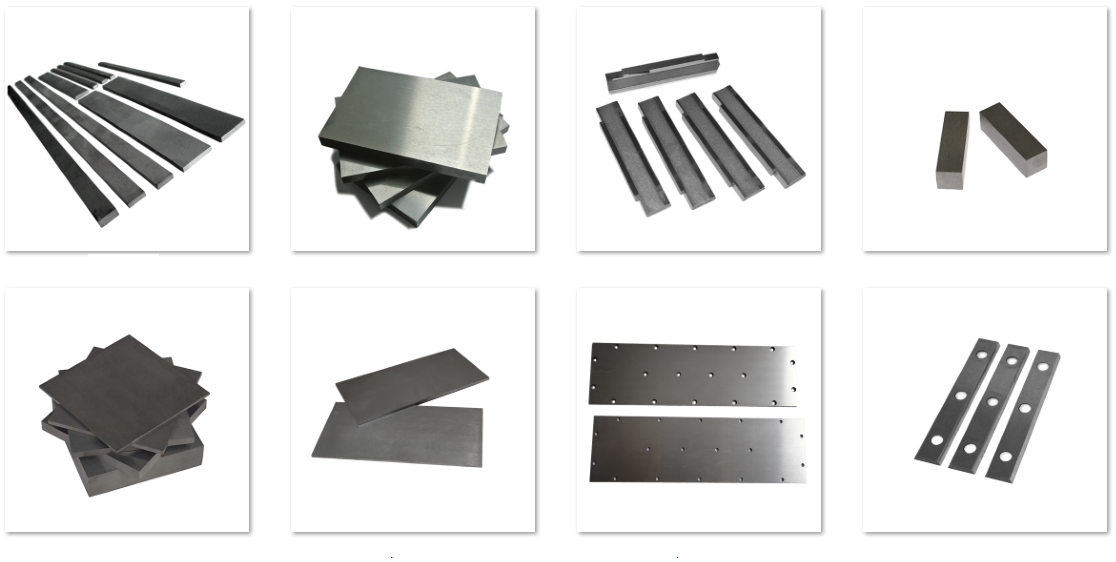

Kev piav txog

Phaj tungide carbide phaj uas muaj cov kev cuam tshuam zoo thiab muaj zog cuam tshuam tsis kam, tuaj yeem siv rau hauv kho vajtse thiab cov qauv kev tuag.

Lub phaj tungsten carbide phaj yog dav siv nyob rau hauv electronics kev lag luam yuav tsum tau ua kom tsis txhob muaj kev puas tsuaj, ei tungosity thaiv, Ei li poricon steel ntim, ei li poricon steel ntim yuav tsum tau ua kom nruj thiab cov pob txha caj dab

Vim li cas thiaj xaiv cov khoom siv tungsten carbide cov khoom?

Cemented carbide muaj cov yam ntxwv zoo heev xws li kev ua kom muaj zog, kub ua rau, thiab nws tseem muaj lub hardness siab ntawm 1000 ° C. Yog li ntawd, nws yog dav siv hauv tshuab. Lub zog ntawm lub cev ntawm tungsten carbide muaj tsawg kawg yog 3 zaug ntawm cov hlau. Nws tuaj yeem ua rau txhua hom phiaj carbide.

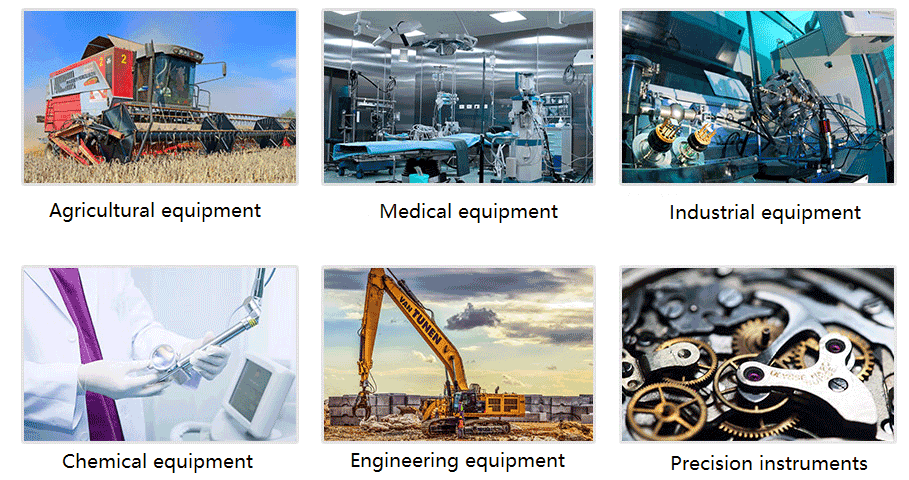

Cov duab rau siv

Cov ntaub ntawv loj: (OEM yog txais)

| Qhov tuab | Qhov dav | Qho ntev |

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

| 3.0-4.0 | 250 | 600 |

| 4.0-6.0 | 300 | 600 |

| 6.0-8.0 | 300 | 800 |

| 8.0-10.0 | 300 | 750 |

| 10.0-14.0 | 200 | 650 |

| > 14.0 | 200 | 500 |

Cov Ntawv Thov

Chuanegrui txoj kev cai tso tseg carbide Phaj Futures

1. Zoo heev thermal stability thiab kub deformation kuj.

2. Kev ntsuas kub ntawm cov tshuab ntsuas kub siab.

3. Zoo thermal poob siab tsis kam.

4. Siab thermal conductivity.

5. Zoo heev oxidation tswj lub peev xwm.

6. Corrosion tsis kam ntawm cov kub.

7. Zoo heev corrosion tiv thaiv tshuaj lom neeg.

8. Kev tsis kam ua siab.

9. Lub neej pabcuam ntev.

Txais tos hu rau peb nyob rau txhua lub sijhawm!

Khoom Siv Ntau Lawm

Kev sib tsoo ntub

Txau Kom Qhuav

Thawb

Nias

Semi-Xovxwm

Ntsiav Sintering

Cov Khoom Siv Ua

Kev drilling

Hlau Txiav

Ntsug sib tsoo

Universal sib tsoo

Dav Hlau Sib Tsoo

CNC Milling Tshuab

Soj ntsuam ntsuas

Kev kub ntxhov

Kev khaatimimimat

Quadratic lub cim kev ntsuas

Cobalt Magic Ntsuas

Metallographic tsom